Spin-Clean is Fluid Power Energy’s lube oil cleaning centrifuge, today’s most cost effective solution for reducing engine wear, extending oil change intervals and reducing hazardous waste. Be environmentally conscious and reduce overhead at the same time.

Benefits: Extends Oil & Filter Life Reduces Hazardous Waste Reduces Engine Wear Removes Solids Below One Micron Durable Construction Easy Installation

What is Spin-Clean?

Spin-Clean is a true centrifuge that, when sized properly, will remove the wear abrasives from the oil down to less than one micron. This will reduce engine wear a minimum of 40 - 50%. The properly sized centrifuge recommended for your engine will not use more than 10% of the engine oil pump output. (10% is the acceptable measure by engine manufactures for by-pass (side stream) oil cleaning.) The 10% taken to supply the Centrifuge does not negatively impact the oil demanded by the engine.

The lube oil cleaning Centrifuge removes the solids from the engine oil using centrifugal force, a force of 1000 “G’s”, or 1000 times the force of gravity. These solids are stored inside of the rotating turbine bowl, which will hold more than 10 times the solids of your engines full-flow filters. The act of exposing the oil to 1000 “G’s” is what results in micron removal less than one. Once the particles have been removed the clean oil is then returned to the oil pan. |

|

|||

Why Run Spin-Clean?

Engine Manufacturers typically install full-flow filters that only remove particles from oil down to 20 - 25 micron. With the addition of Spin-Clean, particles below 1 micron are removed, thus significantly increasing engine life. Time between oil change intervals is also increased saving the user time & money. Equally as important, the addition of Spin-Clean to an engine/package will significantly reduce hazardous waste, which positively impacts our environment. |

|

|||

Importance of Clean Oil

Oil is the life-blood of an engine and the cleanliness of that oil can directly impact the efficiency of the engine, life of the engine, and environment. When properly sized, Spin-Clean cycles the engine oil 4 times per hour ensuring proper solid particle extraction. With proper maintenance, Spin-Clean will increase engine life & oil change interval up to, but not limited to, 40 – 50%. Another Spin-Clean benefit, often overlooked, is its use as a diagnostic tool. The waste material extracted from the oil can be analyzed for several engine related problems. (ie. Coolant leaks, bearing wear) |

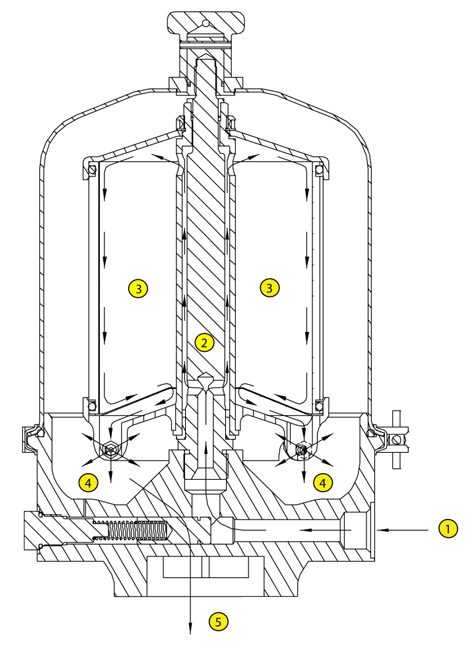

How it Works

1. Pressurized oil enters Spin-Clean on bottom right. (Inlet)

2. Oil travels up the stationary shaft and enters into turbine bowl.

3. The turbine bowl begins to fill with oil and pressurizes.

4. As a result of this pressure, oil is forced out of two nozzles at the bottom of the turbine bowl. This action results in the high rate of speed in which the turbine bowl spins.

When the turbine bowl reaches desired RPM levels, dirty particles down to sub micron levels are forced on to the paper insert, (creating a cake-like substance) which lines the inner wall of the turbine bowl.

5. Clean oil flows out of the turbine bowl, though the two nozzles, and out the bottom of the Spin Clean, back to the oil pan. |

|